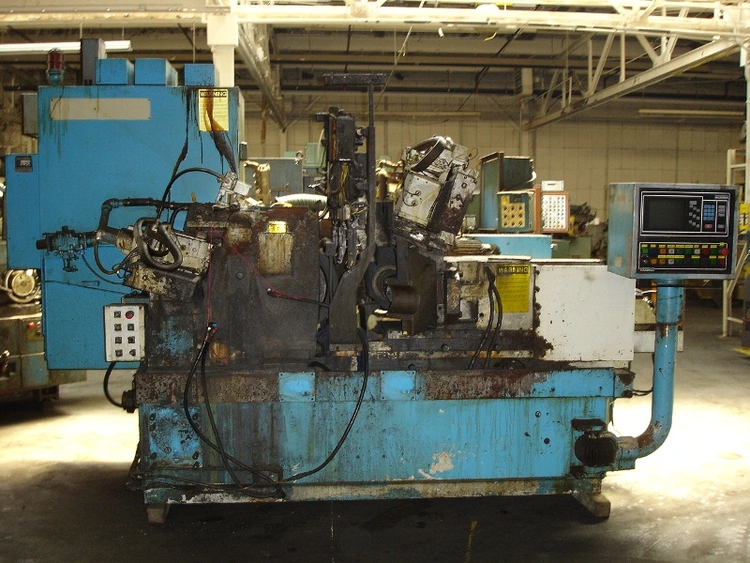

Cincinnati #220-8 Centerless Grinder

220-8CINCINNATIMILACRON

WITH ACRAMATIC 725-G CONTROL

S/N3563A0185-0003Year:1985

STANDARD SPECIFICATIONS

WORK CAPACITY

Maximum work piece diameter…………………………………….. 4.5

Minimum work piece diameter…………………………………….. 0.060

GRINDING WHEEL

Maximum new wheel diameter……………………………………. 24

Minimum worn wheel diameter…………………………………… 17

Maximum wheel width……………………………………………....... 8

Wheel mounting hole diameter……………………………………. 12

GRINDING WHEEL SPEED

Surface speed………………………………………………………. 8500 ft/min.

(Maximum diameter wheel)……………………………………….. @ 1352RPM

GRINDINGWHEEL DRIVEMOTOR

256T Frame –1800RPM………………………………………….20 HP

Drive belts………………………………………………………… 3V850

GRINDING WHEEL DRESSER

Traverse drive motor (variable speed)…………………………….. 56C Frame

Worm gear reduce ratio…………………………………………… 10:1

Traverse rate (across wheel –IPM)………………………………… 1 to 30

Traverse rate (across wheel –mm/min)……………………………. 25, 4 to 762

Maximum traverse distance (across wheel)………………………... 12.5

Maximum profile depth…………………………………………….. 0.50

Diamond holder – single point type………………………………… 0.437Shank

Blade type diamond holder

Electric solenoid……………………………………………………. 0.0005Resolution

Optional stepping motor…………………………………………….0.00001Resolution

Maximum compensation (with stepping motor)……………………. 0.002

REGULATING WHEEL

Maximum new wheel diameter…………………………………….. 15

Minimum worn wheel diameter…………………………………….. 11

Mounting hole diameter……………………………………………..6

Maximum width…………………………………………………….. 8

Optional wheel width……………………………………………….. 10

MaximumRPM(during dressing)………………………………….. 300RPM

MinimumRPM…………………………………………………..…15RPM

Surface speed(ft/min)………………………………………………. 60 to 500

Surface speed(m/min)……………………………………………… 18, 3 to 152

Programmed surface speed is maintained constant as regulating wheel is dressed to smaller diameter.

Drive motor (variable speed)……………………………………….. 3.2 HP

Drive ratio…………………………………………………………… 8.333:1

Regulating wheel housing swivel (work feed angle)..……………… 8 DEGREE to 11/2 DEGREE

REGULATING WHEEL DRESSER

Traverse drive motor (variable speed)…………………………… 56C Frame

Worm drive reducer ratio………………………………………… 10:1

Traverse rate (across wheel –IPM)…………………………….... 1 to 30

Traverse rate (across wheel –mm/min)…………………………. 25,4 to726

Maximum traverse distance……………………………………… 11

Maximum profile depth………………………………………….. 0.50

Diamond holder –single point…………………………………...0.437Shank Diameter

Diamond compensator manual advance dial……………………...0.0005Division

Maximum compensation (with stepping motor)……………….… 0.002

Electric solenoid(optional)…………………………………….… 0.0005

Dresser swivel –degrees………………………………………… 8 DEGREE to 1 1/2-

TWO-WAY COMPENSATOR

Stepping motor……………………………………………………. 200 Steps /Revolution

Harmonic drive ratio……………………………………………… 160:1

Re-circulating ball screw………………………………………….. 8 mm Pitch

Compensator resolution…………………………………………… 0.00001

Positioning rate(maximum)………………………………………. 2.5 in/min.

IN FEED(Optional)

Stepping motor……………………………………………………. 200 Steps/Revolution

Harmonic drive ratio………………………………………………. 160:1

Re-circulating ball screw………………………………………….. 8 mm Pitch

Compensator resolution…………………………………………… 0.00001

Positioning rate(maximum)………………………………………. 2.5 in/min.

Rapid advance/retract distance(maximum)……………………….. 1.5

Rapid advance/retract rate…………………………………………. Fixed

Number of feed rates (plus gap eliminator rate)…………………… 3

Maximum feed rate (gap eliminator)………………………………. 2.5 in/min

Maximum feed rate (fast feed)…………………………………….. 2.5 in/min

Maximum feed rate (medium and slow feed)……………………… 0.9999 in/min

SWIVEL PLATE

Swivel to front (measured at adjustor)…………………………….. 0.50

Swivel to rear (measured at adjustor)……………………………… 0.50

Swivel indicator(division dialindicator)…………………………..0.0001

LOWER SLIDE

Maximum travel……………………………………………………. 9.05

Slide clamps(2)……………………………………………………. Manual

UPPER SLIDE

Maximum travel………………………………………………5.75

Slide clamps(2)……………………………………………… Manual

HYDRAULIC SYSTEM

Reservoir capacity…………………………………………… 29.5 gallon

Oil specification……………………………………………… CM P-38

Viscosity(S.U.S@ 100 DEGREE F)…………………………………. 149 to 182

ISO viscosity grade………………………………………….. ISO VG 32

Military spec. equivalent…………………………………….MIL-H-4600IA Type1

Pump capacity (without in feed)……………………………. 4.6 gallon permin.

Pump motor…………………………………………………1.5 HP 1800RPM

Frame……………………………………………………….145T,NemaC Face Mount

Pump capacity (with in feed)…………………………………8.8 gallon per min.

Pump motor………………………………………………… 3HP 1800RPM

Frame……………………………………………………….182T,NemaC Face Mount

Pressure filter……………………………………………….. Throw-Away Type Element

Bypass pressure…………………………………………….. 25PSI

Replacement element…………………………….CM No. 3634910 Schroeder No.CC3

Dual element filter (optional)

Main system pressure………………………………………. 300PSI

LUBRICATION SYSTEM

Reservoir capacity…………………………………………………….. 7.3 gallon

Oil specification……………………………………………………….CM P-47

Viscosity(S.U.S.@ 100 DEGREE F)…………………………………………... 317 to 389

ISO viscosity grade……………………………………………………. ISO VG 68

Military specification equivalent…………………MIL-L-46017 Type 1 Medium

System pressure…………………………………………………….… 300PSI

Lubrication cycle frequency………………………………………….. 5 Times Per Hour

System type: positive displacement, progressive series with cycle complete

pressure switch.

Distributor points:Grinding wheel dresser

Regulating wheel dresser

Swivel plate

Lower slide

Upper slide

In feed positive stop

Lubrication oil is also supplied at a constant pressure to the regulating wheel spindle bearings and drive unit.

Lubrication cycle frequency and points lubricated may vary due too optional/special equipment supplied.

CUTTING FLUID SYSTEM

Tank capacity……………………………………………………… 75 gallon

Pump capacity(flow)……………………………………………… 90 gallon per min.

Pump motor……………………………………………………….. 1/2 HP

Optional system…………………………………………………… Hydrant and sewer

Optional filter system…………………………………………….. Barnes Drill MPE-15

MACHINE WEIGHT

21,250 lbs.

Specifications are deemed accurate, however, subject to verification or prior sale

All exchange units/returns must be shipped within 30 days. All exchange units/returns must be shipped using DDP terms - Grinders Clearing House, Inc. dba GCH Machinery, is not responsible for any customs formalities or shipping costs.

If Grinders Clearing House, Inc. dba GCH Machinery does not receive exchange/core unit back within 30 days, GCH will invoice FULL replacement cost (OUTRIGHT Cost) to customer.

We use cookies to improve your experience. Privacy Policy.