Cincinnati 14x48 Universal Cylindrical Grinder, 14" Swing, 48" Between Centers, Tailstock Dresser

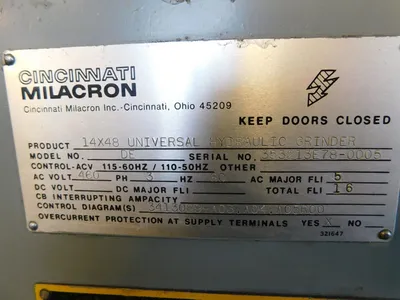

14 x 48 CINCINNATI UNIVERSAL CYLINDRICAL GRINDER

S/N 353213E78-0005 Year:1978

SPECIFICSPECIFICATIONS

Maximum swing overtable…………………………………………… 14 15/16

Maximum diameter machine willgrind with:

Full size wheel…………………………………………………………14

Minimum diameter machine willgrind with:

Either full size or worn outwheel……………………………………… 0

Nominal distance betweencenters…………………………….………. 48

Distance from floor tocenters…………………………………………. 42 1/4

Swivel table graduated toangle of:

Toward wheelhead……………………………………………..…….. 10 degrees

Away from wheelhead………………………………………..….…… 3 degrees

Swivel table graduated totaper per foot of:

Toward wheelhead…………………………………………………… 4 1/2 degrees

Away from wheel head…………………………………………….….1 1/4 degrees

STANDARDCATALOG SPECIFICATIONS

Swivel range: (lower swivel,right left)……………………………. 90 degrees

(upper swivel, right left)………………………….… 30 degrees

Grinding wheel (dia. x face.x hole)………………………………….. 14 x 2 x 5

CROSSFEED

Automatic in feed at tablereversal

Diameter reduction…………….(low)………………….…………..….0002 to .005

(high)…………………………….…. .005 to .0125

Wheel head movement per turnof cross feed

Hand wheel……………………(low)…………………………….…….050

(high)…………………………………..250

HEAD STOCK FOOTSTOCK

Taper hole in head stock foot stock spindles………………………. #9 B S

Number of work rotationspeeds…….……………………………….. Variable

Head stock spindle nose,American lathe standard…………………... 5

Head stock swivel: (towardwheel head).…………………………….. 90 degrees

(away from wheel head)……….………………… 30 degrees

TABLE

Number of table traversespeeds……………………………………… Infinite

Range of table traversespeeds (in per min)……………………….….. 3 – 240

Minimum movement required toreverse table….………………….… 3/32

Accuracy of table reversal atall traverse rates…..………………..….. .004

Independent right hand andleft hand tarry, seconds….…...……….…. 0 to 5

Mechanical hand tabletraverse per revolution of hand wheel:

Rapid…………………………………………………………………..15/16

Slow…………………………………………………………………….0.2

POWERREQUIREMENTS

(Electrical equipmentincluded with machine)

Wheel headmotor…………………………………….. 7 1/2 HP – 1730 RPM220/440

Hydraulic pumpmotor……………………………………………..…. 1 HP

Head stock motor…………………………..……………………..……3/4 HP

Internal grinding attachmentmotor………………..………………..… 2 HP – 3750 RPM

Cutting fluid pumpmotor……………………………………………… 1/4 HP

swing down attachment.

Left and right tarry at endof table stroke.

Self contained coolant andhydraulics.

Traverse.

Vari speed head stock.

Tail stock dresser.

Swing down ID spindle.

Live/Dead Center headstock.

G.C.H. has many Universal’savailable in stock, as well as replacement parts for these machines. If this machine does not fit your needs,please don’t hesitate to ask your salesperson about others.

Specificationsare deemed accurate, however, subject to verification or prior sale.

All exchangeunits/returns must be shipped within 30 days. All exchange units/returns mustbe shipped using DDP terms - Grinders Clearing House, Inc. dba GCH Machinery,is not responsible for any customs formalities or shipping costs.

If Grinders ClearingHouse, Inc. dba GCH Machinery does not receive exchange/core unit back within30 days, GCH will invoice FULL replacement cost (OUTRIGHT Cost) to customer.

We use cookies to improve your experience. Privacy Policy.