TURNKEY GRINDING SYSTEMS

You will work with one vendor: GCH Machinery.

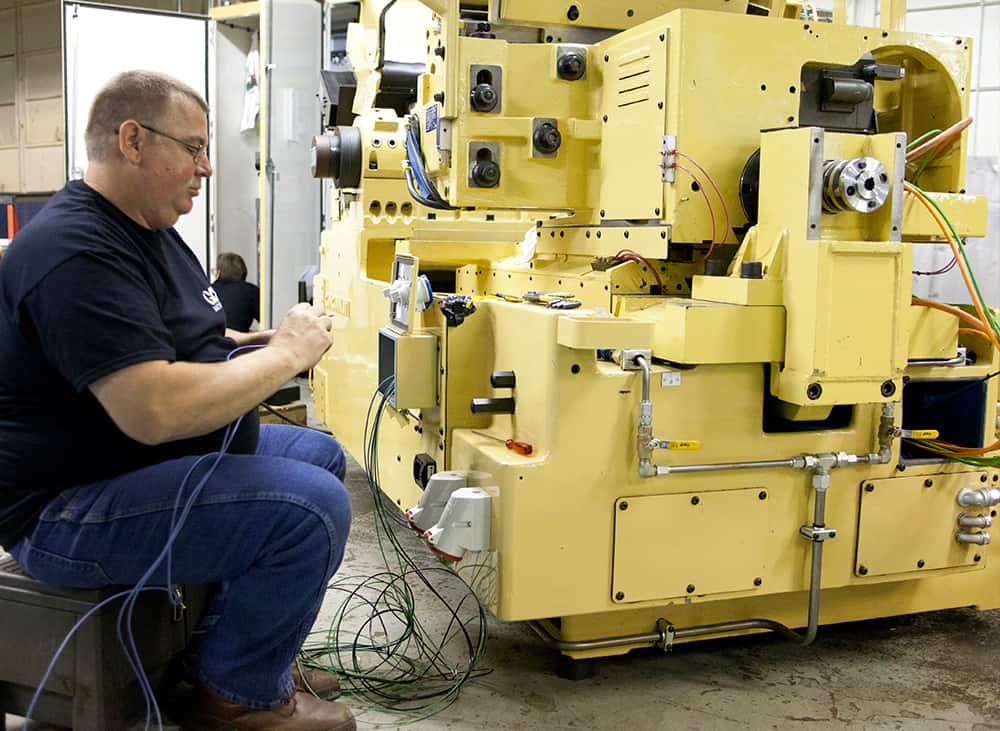

GCH Machinery provides turnkey grinding systems that are designed to increase productivity, reliability and accuracy. While each system is tailored to meet customer specifications, however stringent, our focus on improved part quality and increased profits for our customers never waivers. GCH Machinery delivers complete turnkey grinding systems, including centerless, ID, OD (cylindrical), surface and double disc grinders, worldwide that can run parts nearly immediately, without the need to integrate outside modules such as automation. GCH takes total responsibility for the entire project, from design through installation.

Below is just a sample of the modules we can add to your turnkey grinding solution:

- Automation

Robots

Gantry loading

- Gaging

Post-process

In-process

- FIS

Factory Information Systems

- Upgrades

Full enclosure

Entrance and exit conveyors

Wheel balancer

Wheel lifter

Wheel changer

Many others

ENGINEERING PROWESS

The GCH Machinery engineering team is made up of individuals who share a passion for grinders and machine tools. Having established, refined and managed grinding operations in a number of industries, our team members bring their individual strengths, be it mechanical or electrical engineering, project management, software, electrical controls, machine building or design, and combine them to concept and build a system that matches your exacting standards. Coming from industry, our degreed engineering team, with more than 150 years of combined experience in grinder rebuilding and remanufacturing, understands the challenges you face and can offer innovative solutions.

ONE-STOP SHOPPING

GCH Machinery manages your entire remanufacturing project from start to finish, including machine design, engineering and build, automation design and integration, electrical design and engineering, controls and software programming, machine testing and runoff, on-site installation, and training and certification services. We take total accountability and responsibility for your project.

Keeping all aspects of your project in house ensures that all components are compatible. More importantly, working with a single vendor means you will have contact only with those who have in-depth knowledge of the entire project, saving you time and money.

Any components or parts needed for your turnkey grinding system will be provided by GCH Tool Group, our sister company. GCH Tool Group shares our Warren, Mich., manufacturing facility, and complies with all of our established best-practice manufacturing methods. All components provided by GCH Tool are manufactured to OEM specifications or better, and are guaranteed for maximum performance.

CUTTING-EDGE SOLUTIONS

Our extensive background in grinders and machine tools, combined with the drive to provide our customers with the most advanced technologies, has led to development of innovative grinding machine upgrades, which can be incorporated into your turnkey grinding solution. Since its establishment more than 55 years ago, GCH Machinery has focused on advancing machine operation and holds patents on a number of innovative upgrades, including:

GCH Machinery works closely with customers and expands offerings to meet the challenges of a dynamic manufacturing environment.

ABILITY TO MEET TIGHT SPECIFICATIONS

As leaders in the field of grinder remanufacturing, we apply our hands-on knowledge to design a machine that will meet the most stringent specifications. In fact, we’ve met specifications as tight as .5μ (micron). Our emphasis on research and development assists us to refine your application, and come up with revolutionary designs and cutting-edge processes that allow you to meet even the most demanding specifications and tolerances.

WORLD-CLASS MANUFACTURING

Continuous improvement, flexibility and innovation are all terms that can be used to describe GCH Machinery’s manufacturing prowess. GCH Machinery follows established World-Class Manufacturing methodologies and techniques. Boasting many years of on-the-job experience, our manufacturing staff, whom we consider artisans, also suggest ways to improve machine performance. GCH Machinery abides by a set of internal controls and international quality standards such as TQC, TRM, JIT and Kaizen.

GCH Machinery houses a multi-million dollar metrology lab equipped with top-of-the-line Carl Zeiss testing equipment, including an ACCURA 9/18/7 coordinate measuring machine (CMM), a RONDCOM 60AS for form measurements and a SURFCOM 5000 for surface finish inspections. No other company boasts a better equipped on-site laboratory.

COMPREHENSIVE APPLICATION ASSISTANCE

Paying close attention to your system and how it will be used has resulted in many customized solutions that make your life easier. It’s this attention to details that sets GCH Machinery apart.

With more than 150 years of combined experience in grinder applications and machine operation, our team will review your application and requirements to discover where improvements can be made. For new part programs, the GCH team can partner with you to develop grinding processes — even those that pose difficulties or challenges – while focusing on quality, production rates and efficiency. The better your grinding processes, the better your profitability.

GLOBAL SUPPORT AND SERVICE

GCH Machinery draws upon local support and contracts field service technicians on five continents who support your system wherever it is located. Our global staff of grinding machine experts, many of them degreed engineers, are experienced in mechanical, electrical, automation and controls systems and understand the importance of fast response times. We work with customers located all over the world.

NOT JUST GRINDING MACHINES

Did you know that we provide expert remanufacturing services for a host of industries, including automotive, medical, fastener, cutting tools, aerospace, electronics, and more? Our experience translates perfectly into the world of machine tools. Let us turn your older machine tools into automated, sophisticated, state-of-the-art production cells to boost production rates, improve product quality and increase repeatability and accuracy.

Contact Us

Request for Quote

Fields marked with an asterisk are required.