While many companies claim to be machine tool rebuilders, GCH Machinery has the unique ability to apply our many years of hands-on grinding experience, innovation and passion to your remanufacturing project. Combining cutting-edge technology with real-world experience, our engineering team can remanufacture and upgrade your grinder in less time than it takes other companies to simply figure out what’s wrong! While the photos below might amaze you, they’re just a sampling of GCH Machinery’s stable of turnkey grinding cells now operating worldwide.

Any good machine tool remanufacture starts with many conversations between the supplier and the customer, and GCH Machinery projects are no exception to that rule. Further, no remanufacturing project begins before GCH examines the application, with the goal of improving both the process and the machine.

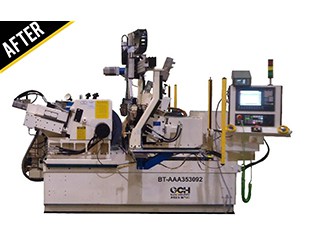

Cincinnati RK 350-20 centerless grinder, remanufactured for a global provider

of pumps and motors

Part: Motor shafts

A global manufacturer whose facilities span the globe contacted GCH Machinery to remanufacture one of its Cincinnati RK grinders. In business for more than seven decades and known for its innovation, the company wanted to turn its “workhorse” grinder into a “race horse” that could keep pace with the company’s new product. GCH determined that a top-to-bottom rebuilding, including several upgrades and the addition of an automation module, would turn this outdated grinder into a 21st-century grinding marvel.

After tearing down the 1985 machine to its base, GCH Machinery replaced all parts with top-of-the-line components. The machine’s antiquated mechanical, hydraulic, pneumatic, lubrication and cooling systems were upgraded with state-of-the-art replacements. Grinder controls were replaced with a full CNC Fanuc controller to allow for easy programming and operation. After careful examination of the company’s production requirements, GCH Machinery recommended that the grinder be outfitted with a custom magazine loader, which would be designed and built by GCH. Also added was a post-process gauge to inspect each part.

Now on the shop floor, this completely rebuilt machine tool cranks out parts flawlessly, shift after shift.

Cincinnati RK centerless grinder for a multinational automotive maker

Part: Camshafts

A major automaker with U.S. roots and manufacturing plants worldwide approached GCH Machinery to remanufacture one of its older Cincinnati RK centerless grinders. The company planned to ramp up production at one of its many global facilities, and required more capacity from its less-than-stellar grinder. The grinder, vintage mid-1980s, would be shipped to GCH Machinery where it would undergo a full remanufacture and integration of an automation system to meet the needs of this customer-focused company.

GCH Machinery first evaluated the current grinding process and noted a number of machine updates that would improve repeatability and robustness, while increasing production rates. Controls were upgraded to a Siemens system to provide full CNC operation, while a new GCH-designed gantry pickup and unload system provided consistent, faster production rates. Implementing these upgrades, along with replacing the grinder’s well-past-prime mechanical, hydraulic, pneumatic, lubrication and cooling systems, turned this older machine into a modern, automated grinding cell.

What was delivered to this automaker was a state-of-the-art machine that exceeded OEM specifications and bumped up machine production by 70%.

Do you have a project you would like to discuss?

Learn more about our capabilities in rebuilding, remanufacturing and retrofitting a wide variety of centerless grinding machines, including Cincinnati Milacron, Gold Crown, Van Norman and more or view other Before/After remanufacturing examples.

Contact us or fill out our RFQ form for a quote.